Brake Slack Adjuster TM042410/F2813 – Precision Manual Adjustment for Heavy-Duty Vehicles

Premium Brake Slack Adjuster (OEM TM042410/F2813) – 25-teeth manual adjuster with 14mm bushing. Forged steel construction. ISO/TS16949 certified. Global shipping available.

Basic Info.

- Model NO. TM042410/ F2813

- Type: Brake System

- Material: Forged steel

- Position: Front

- Certification: ISO/TS16949, ISO13485

- Classification: Drum

- Drum Brakes Classification: Brake Drum

- Main Market: South America, North America, Eastern Europe, Mild East, Southeast Asia, Africa, Western Europe, Eastern Asia, Northern Europe, Oceania, Southern Europe, Central America, South Asia, Domestic Market

- Quality: 100% Test

- OEM No. TM042410/ F2813

- Bushing: 14

- MOQ: 50 PCS

- Color Available: Color Available

- Package: Neutral Packaging or Brand Box

- Teeth: 25

- Arm Length: 145

- Usage: Manual

- Color: Golden & Black

- Transport Package: Carton Packaging

- Specification: 1 Holes 25 Teeth

- Origin: China

- HS Code: 87083099

- Production Capacity: 50000 pieces/Year

Product Description of Brake Slack Adjuster

Brake Part-Truck & Trailer Manual Slack Adjuster with OEM Standard (KN44042)

Original No. TM042410/ F2813

- The manual slack adjuster is used for heavy duty truck and trailer.

- The conventional color is zinc plated.

- We can produce great many kinds of manual slack adjusters according to customer’s requirments.

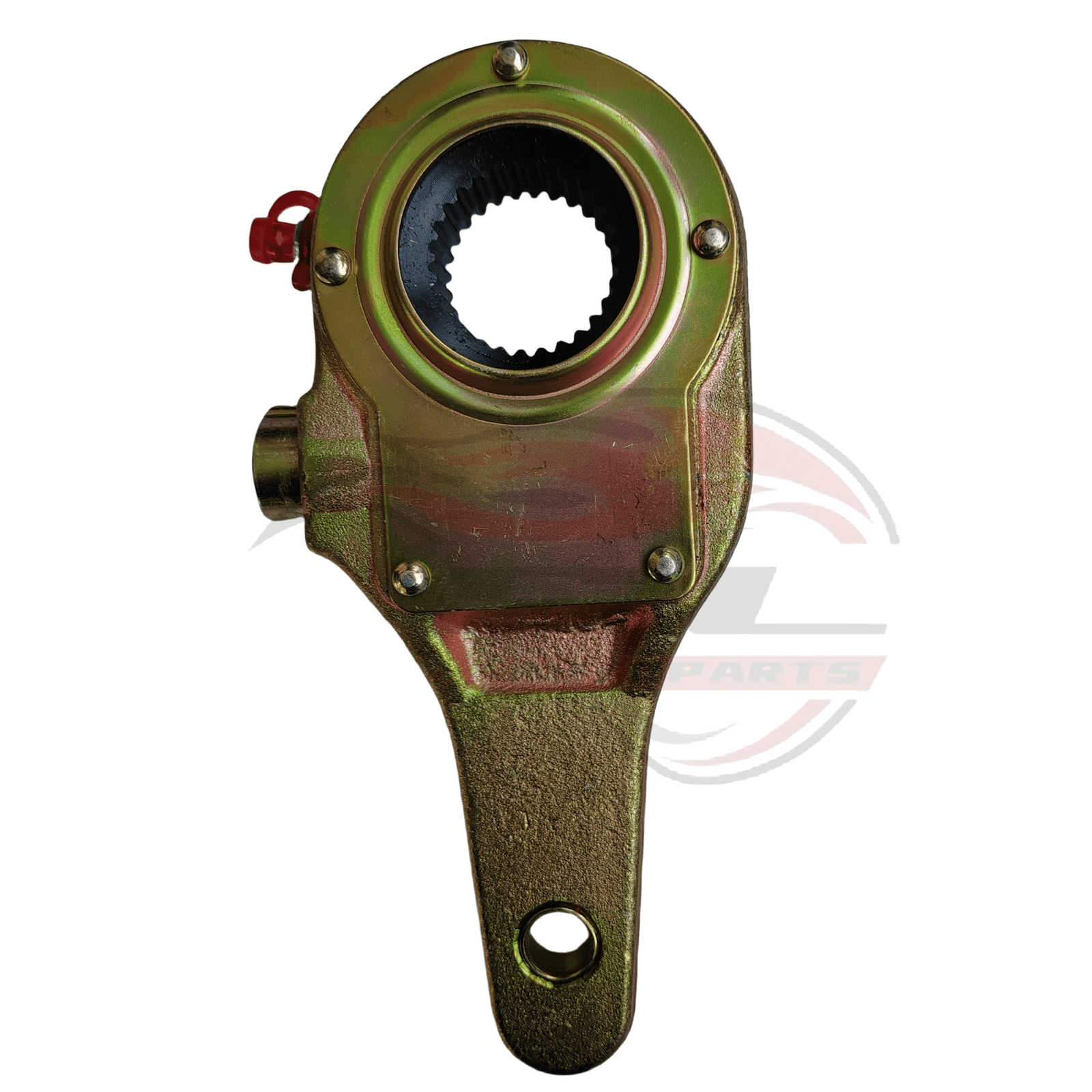

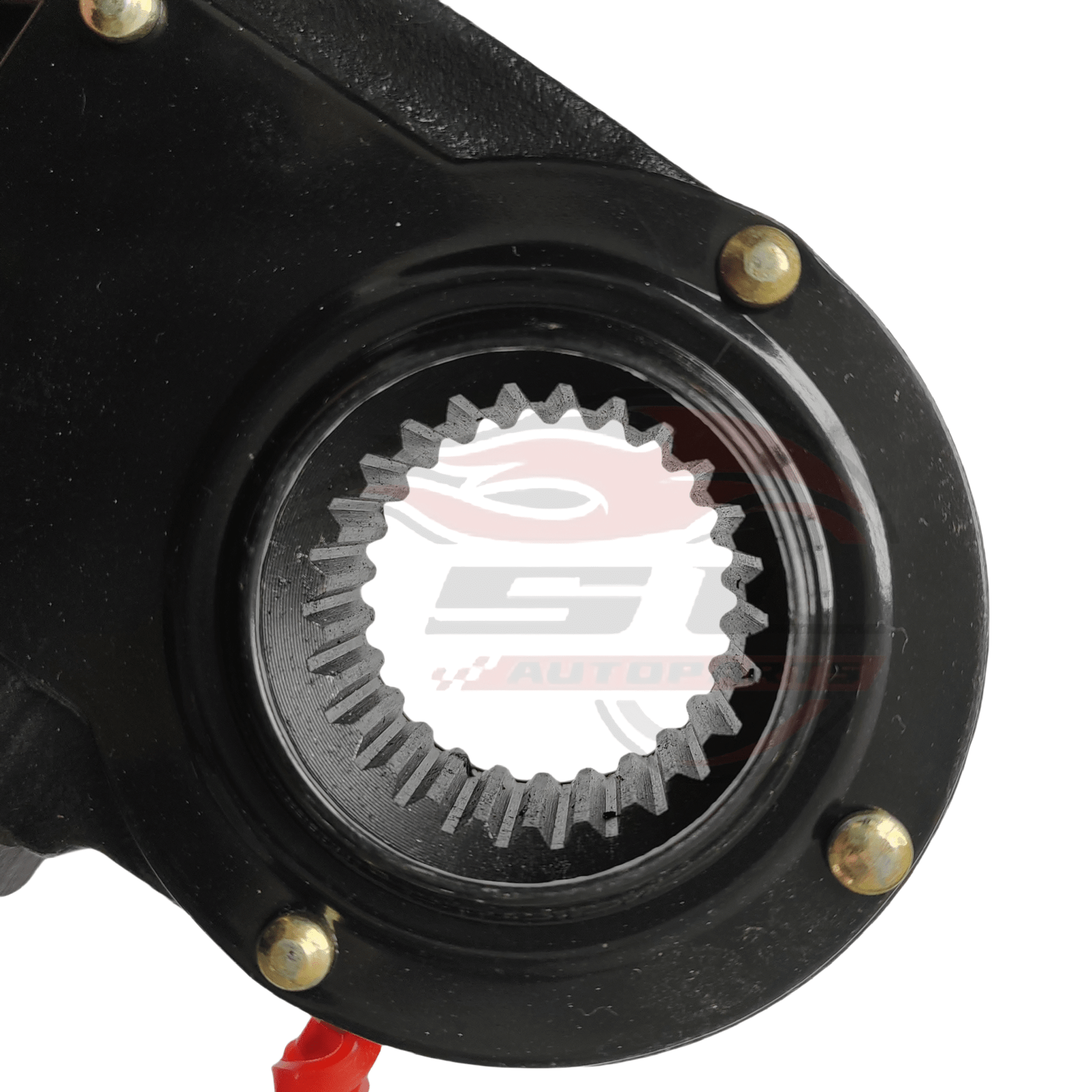

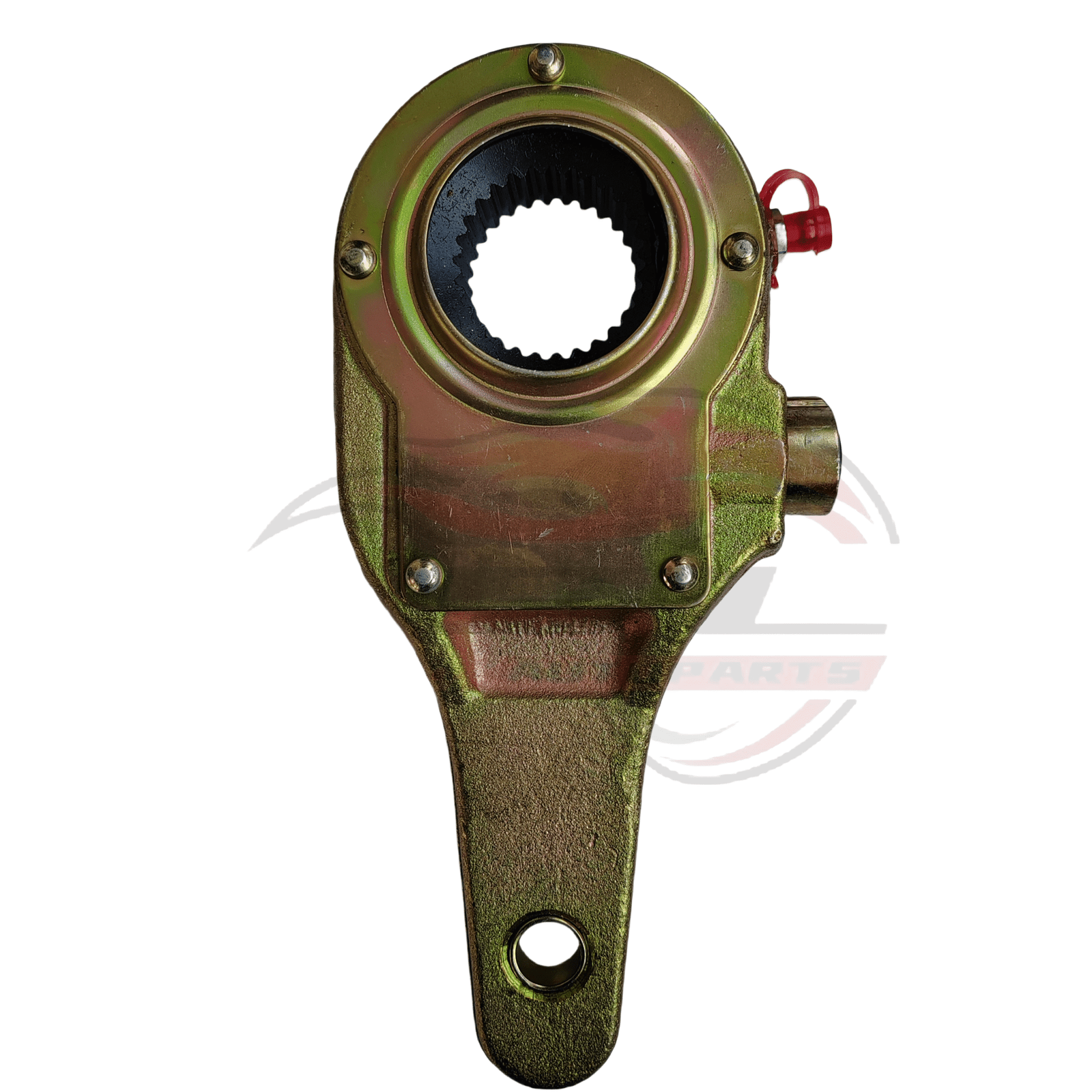

Photos Show of Brake Slack Adjuster

This product is a premium Brake Slack Adjuster with OEM numbers TM042410 and F2813, designed specifically for precision manual adjustment in heavy-duty trucks and trailers. Manufactured from high-strength forged steel, this brake slack adjuster ensures reliable braking performance by enabling exact manual adjustment of brake clearance between the brake shoe and drum. Certified to ISO/TS16949 and ISO13485 international standards, this component meets the most rigorous quality and safety requirements for commercial vehicle applications.

The technical specifications of this brake slack adjuster feature a 25-tooth spline design with a 14mm bushing and a standardized arm length of 145mm. Designed for front-position drum brake applications, it features a durable zinc-plated finish with golden and black coloring for corrosion resistance and professional appearance. The single-hole configuration with 25 teeth provides optimal performance for heavy-duty braking systems, ensuring consistent and reliable operation under demanding conditions.

With a minimum order quantity of 50 pieces, this brake slack adjuster is securely packaged in protective cartons, available in either neutral packaging or custom brand boxes according to customer requirements. Produced in China with an annual production capacity of 50,000 units, the product is available for global shipping to markets throughout North and South America, Europe, Asia, Africa, and Oceania, serving commercial vehicle operators and maintenance providers worldwide.

In addition to the primary OEM numbers (TM042410/F2813), this brake slack adjuster is cross-referenced with numerous alternative part numbers from various manufacturers, ensuring broad compatibility with different truck models and brake systems. The manufacturer maintains comprehensive production capabilities to create various types of manual slack adjusters according to specific customer requirements and application needs. Each unit undergoes 100% quality testing to ensure optimal performance and durability, providing reliable brake adjustment solutions for commercial vehicles across global markets.

Except the above item, we can also provide following items:

| OE No. | Spline | Clevis Bushing | Application |

| 72875 | 1 1/2-10 | 14×6 | |

| 79005 | 1 1/2-10 | 14×6/7 | |

| 72166 | 1 1/2-10 | 12.7 | |

| 72678 | 1 1/2-10 | 12.7 | |

| 79011 | 27 | 14 | |

| 79207 | 26 | 14 | |

| 72702 | 1 1/2-10 | 14×6 | |

| 79017 | 27 | 14 | |

| 79018 | 27 | 14 | |

| 79299 | 27 | 14 | |

| 79300 | 27 | 14 | |

| 72532 | 1 1/2-10 | 14 | |

| 72533 | 1 1/2-10 | 14 |

CROSS REF.

E-9102 KN55001

283411 E-1574 KN44041

278010 E-1063HD KN47081

278321 E-940 KN47011

278302 E-4904 KN48031

278303 E-939 KN48001

286965 KN44051

287899 E-2459HD KN44061

278305 E-539 KN48002

288282 E-2458 KN44071

KN44042

Why Choose Our Brake Slack Adjuster (OEM: TM042410/F2813)?

With years of specialized manufacturing experience, we have perfected the art of producing reliable brake components for the global commercial vehicle industry. Our Brake Slack Adjuster represents the pinnacle of precision engineering and durability for heavy-duty applications. Here’s why professionals worldwide choose our products:

Premium Forged Steel Construction: Crafted from high-grade forged steel, our brake slack adjuster offers exceptional strength and durability. This robust construction ensures reliable performance under extreme conditions, providing extended service life and reduced maintenance requirements for heavy-duty vehicles.

Precision Engineering: Featuring a precise 25-teeth spline design with 14mm bushing and 145mm arm length, our adjuster guarantees accurate brake adjustment and perfect compatibility with various truck and trailer braking systems, ensuring optimal performance and safety.

Quality Certified Manufacturing: All our brake slack adjusters are 100% tested and manufactured under ISO/TS 16949 certification, ensuring they meet the highest international standards for automotive quality and performance reliability.

Global Compatibility & Experience: Designed as exact replacements for OEM numbers TM042410 and F2813, our adjusters are trusted in markets across North America, South America, Europe, Asia, Africa, and the Middle East. Our extensive experience ensures we understand global market requirements.

Proven Reliability: With a production capacity of 50,000 pieces annually, we maintain consistent quality across all our products, backed by comprehensive testing and quality control measures.

Professional Installation Guide for Brake Slack Adjuster

Safety First Protocol:

Park on level ground and securely chock all wheels

Engage parking brakes and completely depressurize air systems

Use appropriate personal protective equipment

Follow all manufacturer safety guidelines

Installation Procedure:

Component Preparation: Thoroughly clean the brake camshaft splines using appropriate cleaning solutions. Inspect for wear, damage, or corrosion. Replace any compromised components before proceeding with installation.

Precise Alignment: Carefully align the 25-teeth spline of the brake slack adjuster with the camshaft splines. Ensure perfect meshing without forcing components together to prevent damage to splines.

Secure Mounting: Slide the adjuster onto the camshaft until fully seated. Tighten the clamp bolt to the manufacturer’s specified torque value using a calibrated torque wrench. Proper torque application is critical for safety and performance.

Linkage Connection: Connect the brake chamber pushrod to the clevis, ensuring proper alignment and smooth operation. Secure with new cotter pins and check for free movement without binding.

Initial Adjustment: Manually adjust the slack adjuster to take up slack until brake shoes contact the drum. Back off according to manufacturer specifications (typically 1/4 to 1/2 turn) to set proper running clearance.

Comprehensive Testing: Conduct thorough testing including:

Visual inspection of all connections and components

Air system pressure and leakage tests

Brake application and release tests in controlled environment

Final adjustment verification and safety check

Maintenance Best Practices:

Regular inspection every 3 months or 25,000 miles

Proper lubrication of moving components as recommended

Periodic adjustment checks and verification

Immediate replacement of worn or damaged components

Maintain detailed service records for each vehicle

Professional Recommendation: Always consult the vehicle manufacturer’s service manual for specific instructions, torque values, and safety procedures. Installation by qualified technicians is strongly recommended to ensure proper function and safety compliance.

FAQ of Brake Slack Adjuster

Q: Are you trading company or factory?

A: We are the manufacturer.

Q: What’s the MOQ for each item?

A: Usually the MOQ is 100pcs for each type. If color box is requested, the MOQ is 200pcs.

Q: What about the delivery time?

A: It’s about 1 to 5 days for the goods have in stock, 15 to 30 days for the goods need to be manufactured based on your order.

Q: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages

before you pay the balance.

Q: What is your terms of delivery?

A: EXW, FOB, CFR, CIF, DDU.

Q: What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q: Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q: Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Final Call to Action (CTA)

📞 Contact us now for bulk orders (MOQ 50 PCS) and competitive pricing!

🌍 Ships globally – Serving North America, Europe, Africa, Asia, and more.

🛠️ OEM & Custom Solutions Available – Tailored to your requirements.

🚛 Join Our Facebook Community for Brake System Professionals! 🛠️

This Slack Adjuster isn’t just a part—it’s a critical safety upgrade for any heavy-duty braking system. Get yours today!

Reviews

There are no reviews yet.