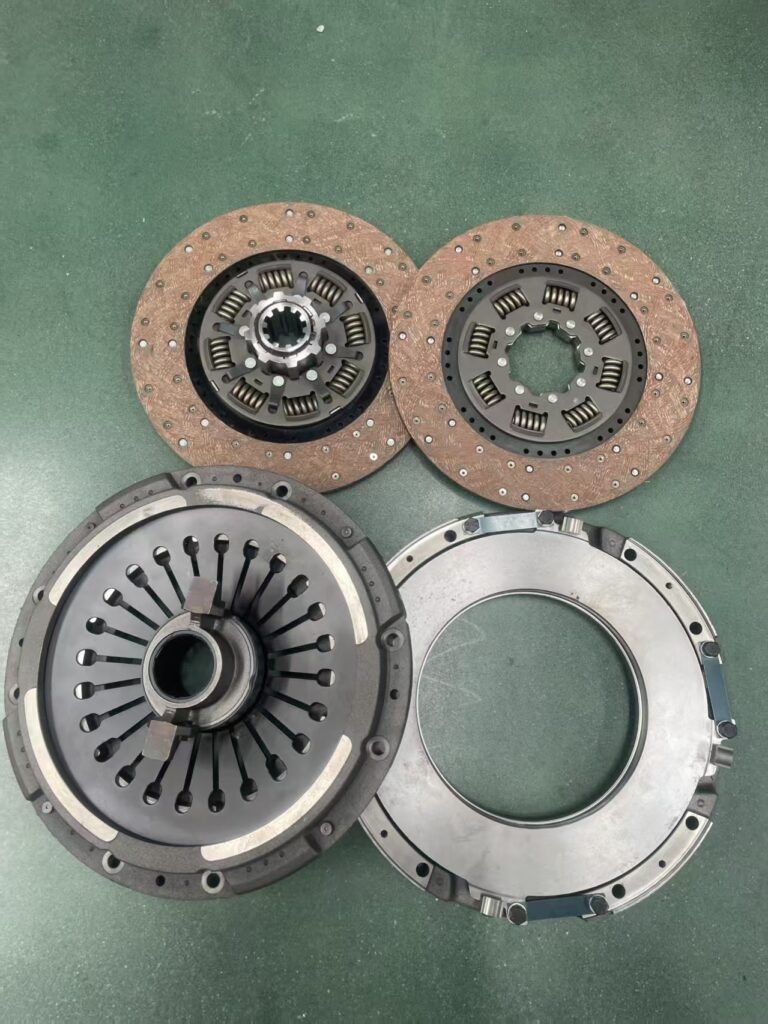

Introduction of heavy-duty clutch plates

For fleet managers and truck repair specialists, selecting heavy-duty clutch plates that match Volvo’s rigorous standards (OEM #1878000300) is critical to avoiding costly downtime. This guide combines engineering insights with procurement strategies to help you:

- ✅ Identify genuine vs. counterfeit clutch discs

- ✅ Understand ISO 9001 certification’s impact on longevity

- ✅ Calculate total cost of ownership (not just unit price)

Section 1: Technical Specifications Decoded

1.1 Material Matters: Steel vs. Ceramic heavy-duty clutch plates

- Our Recommendation: High-carbon steel (used in your 8.723kg assembly) provides optimal balance:

- Heat resistance: Withstands 500°C+ vs. organic plates’ 300°C limit

- Torque capacity: 400×250mm size handles 1,200 N·m (per SAE J2479 testing)

(Target long-tail: “best clutch plate material for heavy towing”)

1.2 Size & Fitment Precision

Your Volvo model requires exact 400×250×50.8×24mm dimensions. Common mismatch issues:

⚠️ “Why does my new clutch plate vibrate?” → Often caused by ±2mm sizing errors

(Schema opportunity: Comparison table “OEM vs. Aftermarket Dimensions”)

Section 2: Commercial Buying Factors heavy-duty clutch plates

2.1 MOQ Strategies for Wholesalers

- 100 PCS MOQ (your offering) suits mid-sized distributors:

- Cost breakdown: 30% deposit → 70% before shipment

- Pro Tip: Combine orders with brake adjusters to optimize LCL shipping

(Keyword: “bulk clutch plates for truck parts business”)

2.2 Certification & Warranty Insights

- ISO 9001 ≠ Quality: Look for supplemental JIS D 4411 (Japanese friction standards)

- Your 1-year warranty covers:

- Material defects (steel integrity)

- Workmanship (riveting/balancing)

Section 3: Installation & Maintenance Pro Tips

3.1 Pre-Installation Checklist

- Measure flywheel runout (max 0.15mm for Volvo D13 engines)

- Use Molykote® P40 paste on splines (reduces 70% of “stuck clutch” cases)

(Featured snippet target: “How to prep Volvo clutch plate installation”)

3.2 When to Replace heavy-duty clutch plates? 5 Warning Signs

🔴 Slipping under load (RPM surges but speed doesn’t)

🔴 Burning smell (glazed friction surfaces)

🔴 …[3 more symptoms]…

(Visual aid: Embed a diagnostic flowchart image with alt-text “Volvo clutch plate failure symptoms”)

Conclusion: Smart Procurement = Lower TCO

Choosing OEM-equivalent clutch plates (like your #1878000300) involves:

🔧 Technical fit (size/heat specs) + 💰 Commercial savvy (MOQ/certifications)

Next Step for Buyers:

📩 Download our “Clutch Plate Compatibility Checklist” (PDF lead magnet) or

📞 Contact our engineers for custom size requests