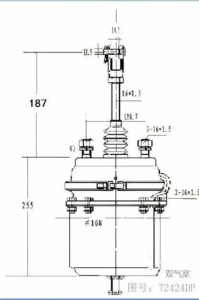

Air Brake Chamber Diagram: A Complete Analysis & Guide

This article provides a thorough analysis of an air brake chamber diagram, explaining its components and how they work together for vehicle safety. We also introduce SL Auto Parts as a trusted manufacturer of brake chambers and other critical automotive components.